EPP Antistatic Tray

Thermoinsulating materials for buildings, manufactured from EPS, used as insulating pannels on terraced roofs with counterslope.

Multiple advantages

1. Shorter execution time, resulting in significant reduction of labour costs.

2. Minimal heat loss, on ceiling level.

3. Fast return of investment cost.

4. Decrease of floor static charges, due to significant reduction of layer weight.

Constantly searching for innovative products, HIRSCH Porozell manufactures high density EPS ornaments, for facades and interiors. Our ornaments include, columns, friezes among many others, all executed in the shortest time, delivering outstanding quality. Besides numerous existing models, we create custom ones, according to every customers need.

Whether it may be straight or curved lines, big and small, our EPS ornaments can take any shape. Using only the lattest technology, our products are made out of high density EPS, thus offering high durability. They can be applied using silicone (with no solvents) and can be custom painted in the desired colour.

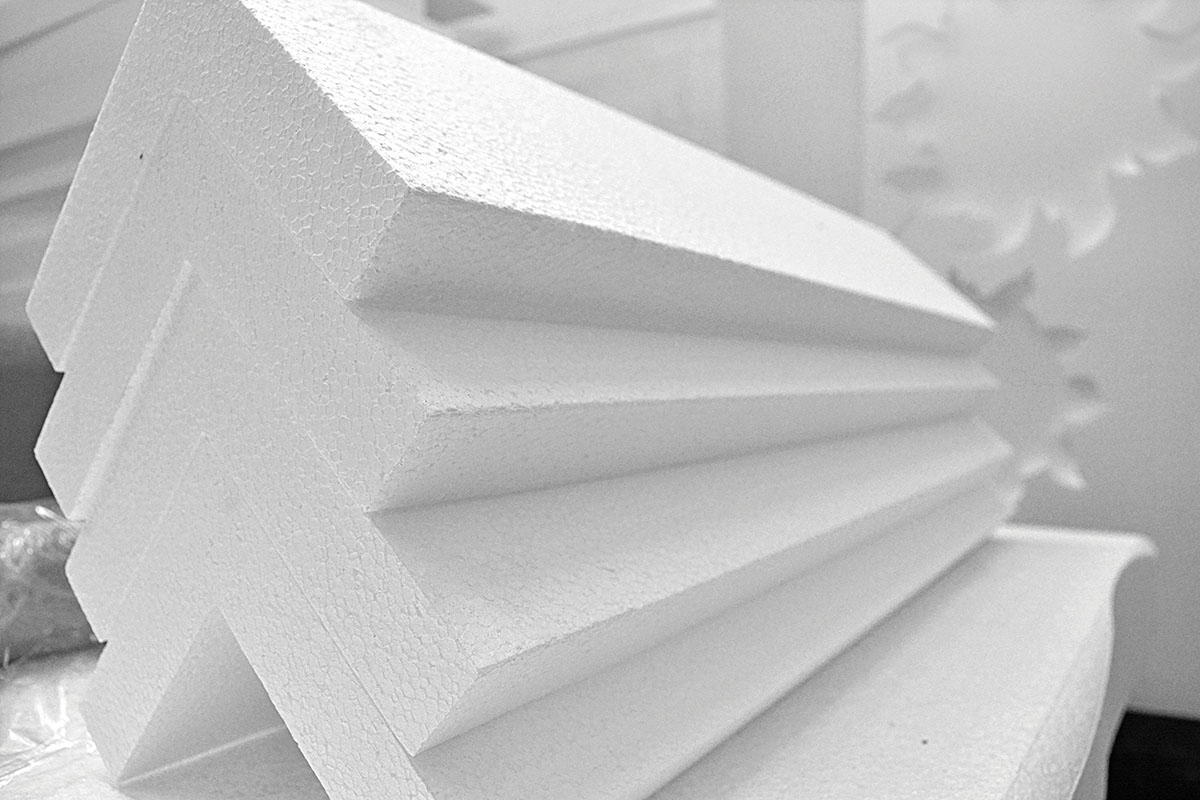

Because of its unique binding system, EPS 80 Nut si Feder offers multiple advantages:

1. Eliminates thermal bridges.

2. Assures facade flatness.

3. Reduces the numer of dowels needed per m2.

4. Garanties the stability of the resulting thermal system, reducing the risk of cracks occurring in the binding area.

Thermozell is the ideal raw material for the production of light insulating concrete, made from recycled EPS grains. The EPS grains are treated with special additives and are mixed with the concrete on site. The product is used in new and old buildings, for interior and exterior floor insulation.

| Technical Data | 160 rapid | 250 rapid | 400 rapid | 600 rapid |

|---|---|---|---|---|

| Measurement value of themal conductivity W/mK | ≤ 0,060 | ≤ 0,090 | ≤ 0,120 | ≤ 0,180 |

| Dry filling density mix / mix in accordance EN 1097-3 kg/m³ | cca. 145 | 210 – 5 % | 275 – 5 % | 400 – 5 % |

| Raw density of fresh mortar kg/m³ | cca. 170 | cca. 350 | cca. 420 | cca. 660 |

| EPS density in accordance EN 1602 kg/m³ | cca. 160 | 250 – 10 % | 350 – 10 % | 500 – 10 % |

| Compresion resistance in accordance EN 826 kPA | ≥ 120 | ≥ 200 | ≥ 500 | ≥ 1.200 |

| Difusion of water vapour resistance my | µ = 7 | µ = 7 | µ = 7 | µ = 14 |

| Fire behaviour cf. EN 13501-1 | E | E | A2 | A2 |

| Bag content | 200 litri | 200 litri | 200 litri | 200 litri |

| Bags per palet | 12 buc. (2,4 m³) | 12 buc. (2,4 m³) | 12 buc. (2,4 m³) | 12 buc. (2,4 m³) |

| EPS material granulation | ≤ 8 mm | ≤ 8 mm | ≤ 8 mm | ≤ 8 mm |

| Minimum thickness | ≥ 30 mm | ≥ 30 mm | ≥ 30 mm | ≥ 30 mm |

| Water addition per bag | cca. 12 litri | cca. 15 litri | cca. 20 litri | cca. 28 litri |

| Binder content per m³ according to specifications CEM I/II 42,5 R 125 kg resp. 52,5 R | 125 kg | 187,5 kg | 250 kg | 375 kg |

| Processing time | min. 15 minute la 20 °C și 65 % rLf | min. 15 minute la 20 °C și 65 % rLf | min. 15 minute la 20 °C și 65 % rLf | min. 15 minute la 20 °C și 65 % rLf |

| Processing temperature | +5 până la +30 °C | +5 până la +30 °C | +5 până la +30 °C | +5 până la +30 °C |

| Covering capacity depends on CM mesurement /construction climate | după 24 de ore | după 24 de ore | după 24 de ore | după 24 de ore |

Ppza 1300- masina automata de ambalat

Masina de ambalat ppza -1300 este folosita pentru a impacheta baxurile de polistiren expandat cu folie, pe patru laturi, printr-o operatie automata, continua, ciclica

Recognized as the technology leader in vacuum and fluidized bed preexpanders, HIRSCH Maschinenbau manufactures plant and machinery that ranks among the most user friendly in the entire market. The world’s best supplier of vacuum preexpander technology, the company guarantees that the material can be processed rapidly and efficiently and at the same time that the quality of the products is exceptionally high.

Recognized as the technology leader in vacuum and fluidized bed preexpanders, HIRSCH Maschinenbau manufactures plant and machinery that ranks among the most user friendly in the entire market. The world’s best supplier of vacuum preexpander technology, the company guarantees that the material can be processed rapidly and efficiently and at the same time that the quality of the products is exceptionally high.

In 1972 the HIRSCH Group was born, in Glanegg Austria. With subsidiaries all across Europe, Romania(5 plants), Germany(6 plants), France(5 plants), Hungary(3 plants), Poland(2 plants), Slovakia(3 plants), Czech Republic(4 plants) Ukraine(2 plants) and Slovenia(1 plant), the HIRSCH Group manufactures EPS for the insulation and packaging business. The company has also established itself, as a technology manufacturer for machines required for the production of EPS.

Staying true to our slogan, “Expanding with ideas”, our company has taken its products and inovative ideas all over the world, providing solutions for global and regional customers alike.

Besides EPS, our products are also manufactured from arcel, expanded polietheline and polypropylene. The HIRSCH brand is known for outstanding quality, impeccable logistics and innovation.

Our commitemen to quality is certified and constantly verified through audit by specialized firms in the industry.

The HESS tipe H 25 KS is a universal testing machine.